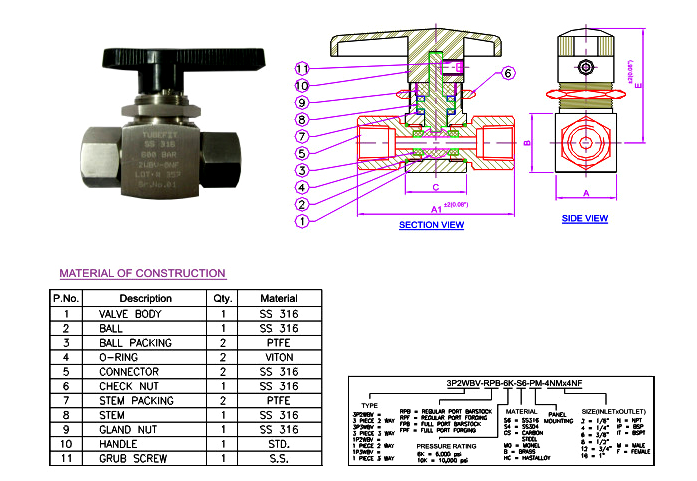

| Features : • SS 316 construction for corrossion resistance, full or reduced bore for excellent flow.3 piece design.peek/delrin seat for better performance. • Ball hard chrome plated for smooth operation. Physical Features : • Pressure rating 400 kg/cm2 Material Options : • Brass, SS 316, carbon steel, bronze, hastalloy, monel, etc. • Optional kel-f, viton packing available with high pressure valves |

Standards : • BS 5750; ISO 9001-2000; MSS SP-99 Testing : • For seat and seal leakage with a leakage rate of 0.1 std. Cm3. • Working pressure : 6000 psi (431 bar) Hydro Tests : • Performed with pure water at 1-1/2 times of the working pressure. • Other tests like helium, seismic are availbale upon request. End Connections : • End connections available in NPT / BSPP / BSPT / JIC / SAE |

| A1(Male) | A1(Female) | Tubefit part no. | C | Size | E | L | A' | ORIFICE | B' |

| 88(3.46") | 76(2.99") | 2WBV-RPB-6K-S6-PM-4NF | 37(1.46") | 1/4" | 49(1.93") | 110(4.33") | 40(1.57") | 5(0.20") | 30(1.18") |

| 88(3.46") | 76(2.99") | 2WBV-RPB-6K-S6-PM-6NF | 37(1.46") | 3/8" | 49(1.93") | 110(4.33") | 40(1.57") | 8(0.31") | 30(1.18") |

| 111(4.37") | 101(3.98") | 2WBV-RPB-6K-S6-PM-8NF | 48(1.89") | 1/2" | 64(2.52") | 180(7.09") | 53(2.09") | 9.5(0.37") | 35(1.38") |

| 118(4.64") | 108(4.25") | 2WBV-RPB-6K-S6-PM-12NF | 60(2.36") | 3/4" | 67(2.64") | 180(7.09") | 60(2.36") | 12(0.47") | 48(1.89") |

| 136(5.35") | 126(4.96") | 2WBV-RPB-6K-S6-PM-16NF | 68(2.68") | 1" | 67(2.64") | 180(7.09") | 68(2.68") | 20(0.79") | 55(2.16") |

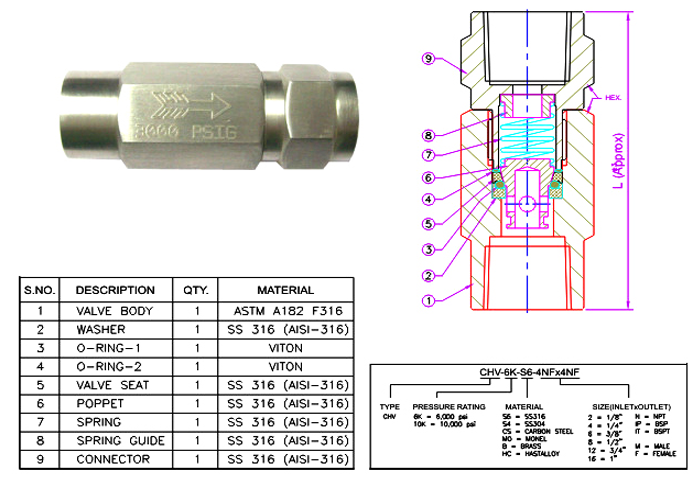

| Tubefit part no. | Size | HEX NPT-F | |

| CHV-6K-S6-2NF | 1/8" | 25.4(1") | 78(3.07") |

| CHV-6K-S6-4NF | 1/4" | 25.4(1") | 78(3.07") |

| CHV-6K-S6-6NF | 3/8" | 25.4(1") | 78(3.07") |

| CHV-6K-S6-8NF | 1/2" | 28.6(1.12) | 78(3.07") |

| CHV-6K-S6-12NF | 3/4" | 32(1.26") | 78(3.07") |

| CHV-6K-S6-16NF | 1" | 42(1.26") | 88(3.46") |

Features :

• check valves are used for controllng flow in one direction only. Check valves should never be used as code safety relief devices.

Note :

• End connections available in NPT; BSPT ; Tube size; BSPP

• 100% valve are factory tested prios to despatch.

• Pressure range from 1,000 to 10,000 psi.

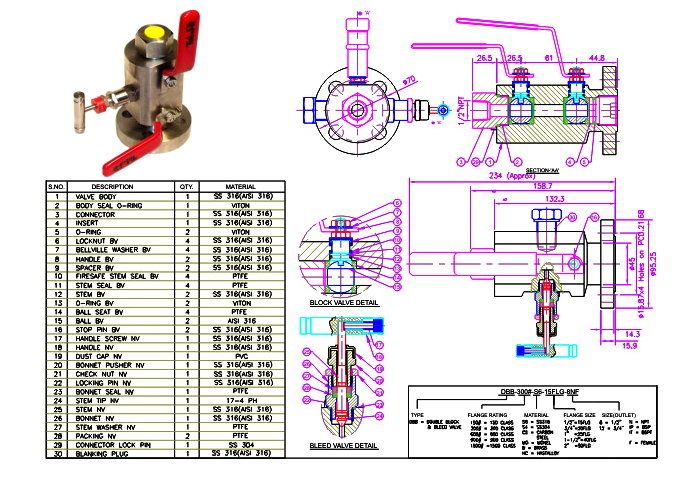

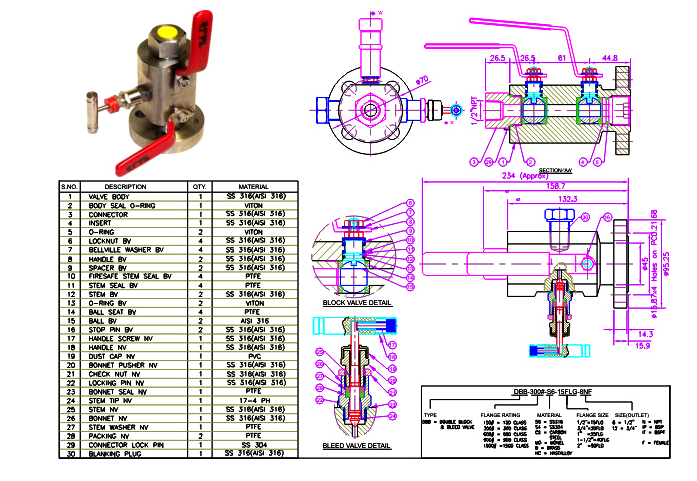

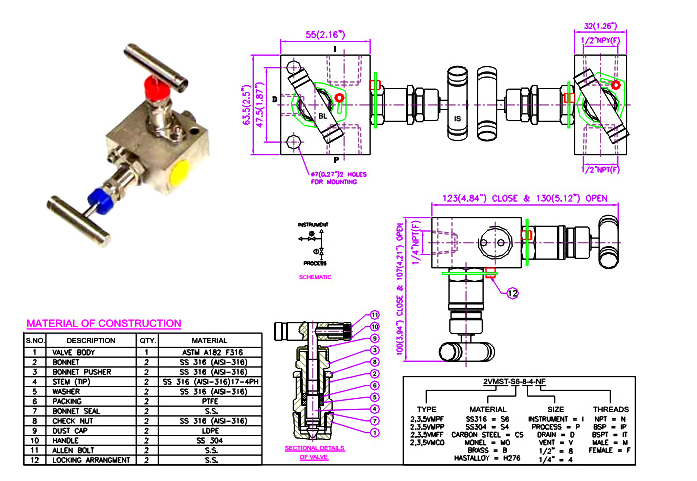

| Features: • It is a combination of needle & manifold valves thus redusing the number of joints. • Spindle : ground and thread rolled.stem tip 17-4ph for long life. • Dust cap protects stem threads from external contamination leak tight seal with low operating torque heat code traceability ball hard chrome plated for smooth opertions. Testing : • Hydrostatic shell test is performed at 1.5 times the working pressure. • Standard Test : each valves is tested with nitrogen at 1,000 psi for seat & packing leakage, with a max. Allowable leak rate of 0 .1 std. Cm3 / min. • Optional test are available upon request |

Lubrication : • Molybdenum disulphide (mos2) Technnical specifications : • Working Pressure : 6000 psi (410 bar) • Stem Packing : PTFE, Grafoil. • Panel mounting on request all valves are 100% factory tested prior to shipment • End Connection : bspp,jic,sae,npt,bspt • Material of Construction : SS 316, SS 304, C.S, F11, Hastelloy, Monel |

| Bonnet Assembly : • Screwed bonnet design. • Bonnet - back seated blow out proof • Spindle - ground and thread rolled. • Spindle tip - non rotating tip shut off type - regulting and soft seated. Packing below thread. • Bonnet pusher - silver plated for anti galling freezing for increased stem cycle life. • Dust cap protects stem threads from externals contamination leak tight seal with low operating torque. Application • Pressure switches, gauges & differential pressure , pressure transmeters suitable for block & bleed assemblies to test pressure source required in sampling line or plug valve. Refineries, liquid petroleum gas processing plant petro- chemical plants systems difficult to shut of due to solid contents dust, rust, dirt etc |

Technical specifications : • End Connection : NPT, BSPT , Socket Weld. • Working Pressure : 6000 psi (431 bar) • Temperature Rating : ptfe 450° f (232 ° c ) grafoil 700 °f (371° c) • Material of Construction : SS 304 , Monel , C.S , SS 316 • Stem Pcking : PTFE Grafoil • Orifice: ø4.7 • All valves are 100% factory tested prior to shipment. • Optional sour gas service valves are available confirming to nace STD MR - 01 - 75 Testing : • Pneumatic seat test is performed at 1/4 of working pressure hydrostatic shell test is performed at 1.5 times the working pressure optional test are available upon request. Lubrication : • Molybdenum disulphide (mo s2) |

| Tubefit part no. | H | W | H1 | PRIFICE L | Size | CV | |

| GRNSV1-6K-S6-4NMX4NF | 77(3.03") | 25.4(1") | 84(3.31") | 4.7(0.18") | 73(2.87") | 1/4"(MxF) | 0.63 |

| GRNSV1-6K-S6-4NFX4NF | 77(3.03") | 25.4(1") | 84(3.31") | 4.7(0.18") | 73(2.87") | 1/4"(FxF) | 0.63 |

| GRNSV1-6K-S6-8NMX8NF | 77(3.03") | 32(1.26") | 84(3.31") | 4.7(0.18") | 102(4.01") | 1/2"(MxF) | 1.80. |

| GRNSV1-6K-S6-8NFX8NF | 77(3.03") | 32(1.26") | 84(3.31") | 4.7(0.18") | 102(4.01") | 1/2"(FxF) | 1.80. |

| GRNSV1-6K-S6-12NMX8NF | 80(3.15") | 38(1.50") | 87(3.42") | 4.7(0.18") | 102(4.01") | 3/4"Mx1/2"F | 1.80. |

| GRNSV1-6K-S6-12NMX12NF | 80(3.15") | 38(1.50") | 87(3.42") | 4.7(0.18") | 102(4.01") | 3/4" (MxF) | 1.80. |

| Tubefit part no. | H | W | H1 | L | Size | CV | ORIFICE |

| 2VM-ST-PP |

| Features : • 2 valve manifolds are designed for remote or separate mounting. • Connecting from process side 1/2" npt(f) and instrument side 1/2" npt(f) connecting system impulse lines and transmitters, having simple two valves configuration which allows for easy block or isolate, bleed or vent valve callbration of a static pressure transmitter or gauge. Bonnet Assembly : • Bonnet : back seated blow out proof. • Spindle : ground and thread rolled. Packing below thread. • Spindle Tip : non-rotating tip shut-off type & soft seated. • Dust cap : dust cap protects stem threads from external contamination heat code traceability. Testing : • Pneumatic seat test is performed at 1/4 of working pressure. Hydrostatic shell test is performed at 1.5 times the working pressure optional test are available upon request. |

Technical specifications : • Size : 1/4" & 1/2" • End Connection : NPT, BSPT, BSP & Socket Weld. • Working Pressure : 6000 psi (413 bar) • Temperature Rating : PTFE 450° f(232°c) Grafoil 700° f (371°c") • Material of Construction : SS 316l, SS 316, SS 304, C.S, F11,hastelloy,monel • Optional sour gas service valves are available confirming to nace mr-01-75 • Stem Packing : PTFE, Grafoil. • Orifice : ø4.7 • All valves are 100% factory tested prior to shipment. Lubrication : • Molybdenum disulphide (mo s2) |